Resources

Full ViewIntroducing rFOIL™ MAX-NT (No-Tear) Reflective Bubble Insulation

January 22, 2024

TORONTO, ON. – Responding to growing market demand for a for a bubble insulation product designed with improved strength to stay securely in place when stapled to wood purlins or framing, Covertech, a division of Balcan Innovations Inc., has launched the first reflective bubble insulation made with a reinforcing scrim mesh. rFOIL™ MAX-NT (No-Tear) Reflective Metal Building Insulation is an exciting new addition to the company’s product offering.

Combining the thermal performance of metalized film, the condensation-controlling properties of bubble, and a strong layer of woven scrim, rFOIL™ MAX-NT is a great alternative to lightweight foam / scrim products. The reinforcing woven layer helps prevent wind-uplift when the material is stapled in place.

“One of our goals at Covertech is to provide our customers with high-quality insulation solutions that are innovative and functional” said Kelly Myers, National Sales Manager at Covertech. “The launch of rFOIL™ MAX-NT is another example of our commitment to meeting the needs of the construction industry, enabling builders to achieve superior performance with our products, and supporting our distribution partners.”

rFOIL™ MAX-NT delivers the thermal value by using a highly reflective metalized film which dramatically reduces heat gain / loss by blocking radiating heat from entering or escaping through the building system. This saves energy, reduces utility bills, and enhances the life of heating and cooling equipment.

Additionally, rFOIL™ MAX-NT helps prevents condensation by providing an airtight thermal break of high-strength bubble between the exterior metal and interior airspace. The reinforcing woven scrim layer adds tear-resistance and tensile strength. rFOIL™ MAX-NT is not affected by moisture and humidity, will not harbor mold and fungi, will not degrade over time, and is safe and clean to handle which makes it easy to install.

rFOIL™ MAX-NT is available in 48” and 72” widths, with various tab options including QuickSeam (tape / tab), and is available with either a white interior facing, or metalized film on both sides.

About the Manufacturer: Covertech, a division of Balcan Innovations, is North America’s leading manufacturer of reflective insulation products. rFoil™ Reflective Insulation is used for a wide range of applications where advanced thermal control is needed, including metal and post-frame buildings, agricultural construction, self-storage, residential and commercial, thermal packaging, automotive, OEM, pharmaceutical and RF shielding applications.

VIEW THIS PRODUCT ON OUR WEBSITE

Full ViewQualifies For Income Tax Credits

As a part of the Inflation Reduction Act of 2022, home renovation projects utilizing reflective insulation are eligible for Energy Tax Credits. These credits are available effective immediately and will expire on December 31, 2031.

Residential applications that qualify for the credits include attics, walls and crawl spaces when properly installed per our installation instructions and per program guidelines.

Our products meet the most recent International Energy Conservation

Code standards – these must be met in order to take advantage of this benefit. To use the tax credit, reflective insulation products must meet the most recent International Energy Conservation Code standard in effect as of the beginning of the calendar year which is two (2) years prior to the calendar year in which such component is placed in service.

You may claim the energy efficient home improvement credit for improvements to your primary residence. Your primary residence is where you live the majority of the time.

For the energy efficiency home improvement credit, the home must be:

- Located in the United States

- An existing home that you improve or add onto (not new construction) and must be your primary residence.

To learn more about the Inflation Reduction Act of 2022, we suggest you view these links to understand how the Home Energy Tax Credits work, and the annual limits.

Click here for the ETC Certificate.

Full ViewHVAC Air Duct Insulation Catalogue & Guide

All Encompassing HVAC AIR duct reflective insulation guide and catalogue

Covers Big-6, Big-8 and 2290 reflective insulations. Includes Product Specifications, Installation Methods, Part Numbers, and more in one downloadable guidebook.

For Residential and Commercial Applications.

| View | rFOIL® Reflective Insulation Catalogue for HVAC/Air Ducts |

| View | See What Industry Insiders Have to Say About rFOIL® products versus Standard FSK type wrap |

Full ViewBUYER BEWARE! The product – Ultra NT Radiant Barrier

Other products, distributed by other building supply companies, claim to be Ultra NT Radiant Barriers. While the name might be similar, these products are not the same as our Covertech, rFOIL Ultra NT Radiant Barrier.

If it doesn’t say… “rFOIL® Ultra NT Radiant Barrier” and have the Covertech logo then it isn’t a Covertech product.

When in doubt, contact Covertech to ensure you have an rFOIL® product.

Read more about “Ultra NT Radiant Barrier” and the full press release here.

View more about RF SCIF Barriers here.

Full ViewRIMA Certificate of Verification

Covertech has been awarded the RIMA 2024 Certificate of Verification for its participation in the ASTM/EIMA-I verification program.

This certificate is managed by the Safety Equipment Institute (SEI) and encompasses the successful completion of annual laboratory testing to validate product conformance with ASTM standards.

View Category I Report: Reflective Insulation

View Category II Report: Radiant Barriers: Vapor Transmitting (perm >5) and Vapor Retarder (perm <1)

Full View Online Education

Covertech is an industry leader in the manufacturing of Reflection Insulation (Rfoil) and Radiant barriers, Film Extrusion and Protective Packaging. Established in 1990, Covertech operates from its modern facility in Toronto, Canada from where it ships finished products to its customer base around the world. This one hour course on Radiant Barriers and Reflective Insulation provides an overview of the benefits of installing reflective insulation and radiant barriers into the building envelope to reduce energy consumption, operation costs, and the structure’s carbon footprint.

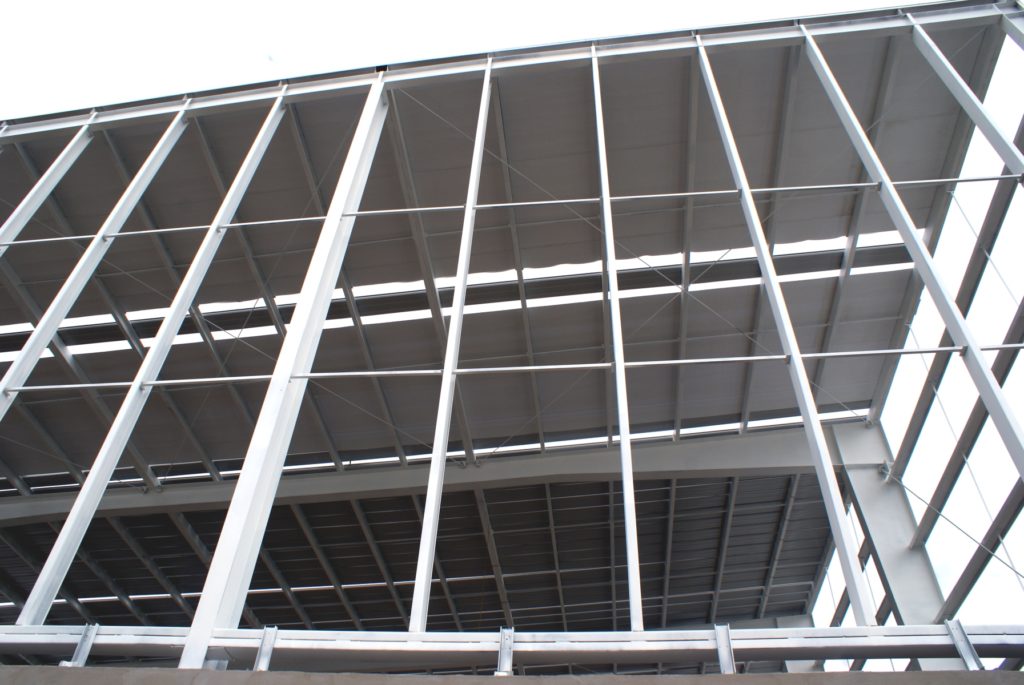

Full ViewMetal Buildings

Metal Buildings and rFOIL

After reading these articles we expect that the next time you think of Metal Buildings you will think of rFOIL. Please, read on…

| View | Using rFoil in Metal Buildings – Frequently Asked Questions |

| View | Metal Buildings and Condensation – Frequently Asked Questions |

| View | Reflective Insulation 101 (MetalMag magazine January 2009) |

| View | Effects of Reflective Radiant Barrier on Heat Loss in Attic Floors and Metal Building Installations |

| View | “KEEPING COOL” Article |

| View | Using Reflective Insulation in Pre-engineered Metal Building Systems |

Full View Saving Energy

Help the Environment and Make Life More Comfortable

Saving energy is more than just about saving money. It’s about being more efficient with our natural resources, conservation, and being environmentally conscious. Reflective Insulation and Radiant Barriers by rFOIL will help you save energy and together we take one more step forward towards saving our planet.

| View | It’s About Saving Energy |

| View | Reflective Insulation and Radiant Barriers and the Energy Crisis |

| View | Radiant Barriers: Depends on Where You Live |

| View | Radiant Barriers: Performance Revealed |

| View | Effect of Attic Ventilation on the Performance of Radiant Barriers |

Full View Be Informed

Know What’s Important

Radiation is often more important than either conduction or convection when it comes to controlling heating and cooling costs. Use the articles below to help you understand when and why rFOIL products, alone or in combination with other types of insulation, will be your best choice.

| View | Physics of Foil – Understand the Three Modes of Heat Transfer: Convection, Conduction, and Radiation |

| View | R-Value Application & Airspace Requirement Guide (COMPLETE LISTING) |

| View | Definition of a Radiant Barrier |

| View | Glossary of Terms |

Full ViewChoose Reflective Insulation

rFOIL: Safe, Clean, Easy, Effective

| View | The Benefits of Using Reflective Insulation |

| View | Insulation 101 |

| View | Reflective Insulation for Residential and Commercial Applications |

Choose the RIGHT rFOIL Product for the JOB!

Full ViewRadiant Barriers

What is a Radiant Barrier?

A “radiant barrier” is a reflective / low-emittance surface as defined by ASTM where the emittance is 0.10 or less on or near a building component that intercepts the flow or radiant energy to and from the building component.

It should be clearly understood that although a radiant barrier reduces heat loss and gain through the building envelope because it is installed in vented cavities (like attics); it is not an insulation material and has no inherent R-Value.

What is a Radiant Barrier System? (RBS)

A radiant barrier system is a building section that includes a radiant barrier facing an air space. An attic with a radiant barrier on top of the mass insulation on the floor or under the roof is an (RBS). A vent skin wall with a radiant barrier facing the vented air space is also an (RBS).

The distinction between a radiant barrier “material” and radiant barrier “system” is not merely academic. In an attic, the effectiveness of a radiant barrier is significantly affected by the amount of attic ventilation. A vented attic with a radiant barrier is a very different system from an unvented attic with the same radiant barrier.

How does a Radiant Barrier work?

It is important to understand the simplicity of how radiant barriers work and their applications in residential construction. Heat always travels hot to cold and its method of travel is via radiation, convection and conduction. In an attic space, radiation accounts for as much as 93% of the heat flow. The roof temperature’s increase as the sun strikes the roof surface. Roofing materials (shingles and decking) are often poor reflectors, emitting or re-radiating 90% of incoming solar energy. Dark shingles absorb as much as 95% of the incoming solar heat gain. The hot roof materials begin transferring this heat to the coolest insulation below, heating the insulation’s surface in the same manner. The insulation becomes saturated and begins transferring to all surfaces within the interior of the home. The radiant surface temperatures of the walls and ceilings have a direct influence on the comfort level of the occupants and increase energy costs. Even today, most energy conservation programs, while recognizing radiant barriers, continue to overemphasize insulation in controlling heat flow from the attic to a home’s interior. A polished film of metalized foil is the primary component of a radiant barrier system. Compared to a dark surface, metalized foil only emits 3% to 5% of as much radiant energy from its surface. Thus, radiant barriers can block 95% to 97% of radiant heat flow.

During a typical summer afternoon, a properly installed attic radiant barrier system will:

- Reduce attic temperature as much as 30 degrees

- Reduce heat transfer from attic to living space up to 50%

- Reduce heat loads on attic, ducts and equipment up to 50%

- Extend the life of the air-conditioning unit

- Increase the comfort level of the home

NT and Ultra NT radiant barrier brand name products utilizes reflective technology that requires an airspace facing one metalized foil side of the product to work as designed. When installed properly, NT and Ultra NT radiant barrier helps ensure that homes stay comfortable and energy efficient year round.

NT and Ultra NT radiant barrier products, as part of the rFOIL family of products, are recognized for their thermal performance, easy installation, versatility and environmental friendliness and offers a number of advantages over traditional insulations.

Advantages:

Benefits:

Remember, as much as 93% of the total heat gain from the roof decking to the top of the insulation is via radiation, and a radiant barrier will stop as much as 97% of radiant heat transfer. Bulk insulation can only slow heat transfer, and more is not better. Studies have shown that a radiant barrier combined with mass insulation is an effective way to reduce the cost of air conditioning and heating. Read more about good radiant barriers here.

| View | “RADIANT BARRIER” Article |

| View | Radiant Barriers – Proven to Work |

| View | Reflective Insulation and Radiant Barriers and the Energy Crisis |

| View | Definition of a Radiant Barrier |

| View | An Evaluation of Placement of Radiant Barriers and their Effectiveness Reducing Heat Transfer in Attics |

| View | The Home Builders Differential Insulation of the 90’s and Beyond Radiant Barrier and Reflective Insulation |

| View | Radiant Barriers Performance Revealed |

| View | Effect of Attic Ventilation on the Performance of Radiant Barriers |

| View | Study Shows 23-Degree Temperature Drop in Attics with Radiant Barriers |

| View | Effects of Reflective Radiant Barrier on Heat Loss in Attic Floors and Metal Building Installation |

| View | Horizontal Attic Radiant Barrier Installations- Technical Bulletin 1999 |

| View | The Effect of Radiant Barriers in a Attic Application on Exterior Roofing Materials-Technical Bulletin 103 |

| View | Reflective Insulation, Radiant Barriers and Interior Radiant Control Coatings for Use in Reflective Insulation, Radiant Barriers and Interior Radiation Control Coatings (IRCCs) Use In Pre- Engineered Metal Buildings -107 |

| View | Effect of Radiant Barriers in an Attic Application on Exterior Roofing Materials |

| View | Radiant Barriers: Depends on Where You Live |

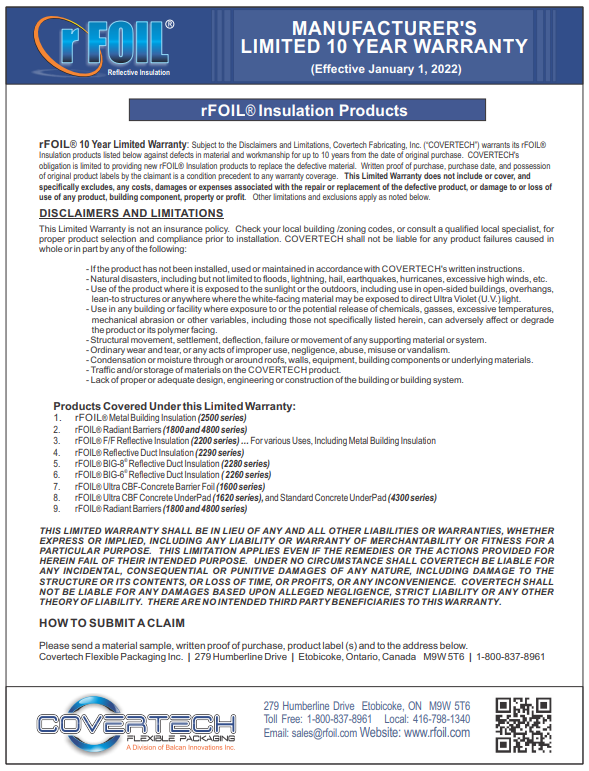

Full ViewStandard Warranty

Both our standard warranty and the 2600 warranty are special in their own way. Choose the product which serves your needs best.

Rest assured that whichever choice you make you will be installing a great insulation product backed by the rFOIL reputation.

2. rFOIL® Radiant Barriers (1800 and 4800 series)

3. rFOIL® F/F Reflective Insulation (2200 series) … For various Uses, Including Metal Building Insulation

4. rFOIL® Reflective Duct Insulation (2290 series)

5. rFOIL® BIG-8 Reflective Duct Insulation (2280 series)

6. r Foil® – Big 6 Reflective Duct Insulation ( 2260 series)

7. rFOIL® Ultra CBF-Concrete Barrier Foil (1600 series)

8. rFOIL® Ultra CBF Concrete UnderPad (1620 series), and Standard Concrete UnderPad (4300 series)

9. rFOIL® Radiant Barriers (1800 and 4800 series)

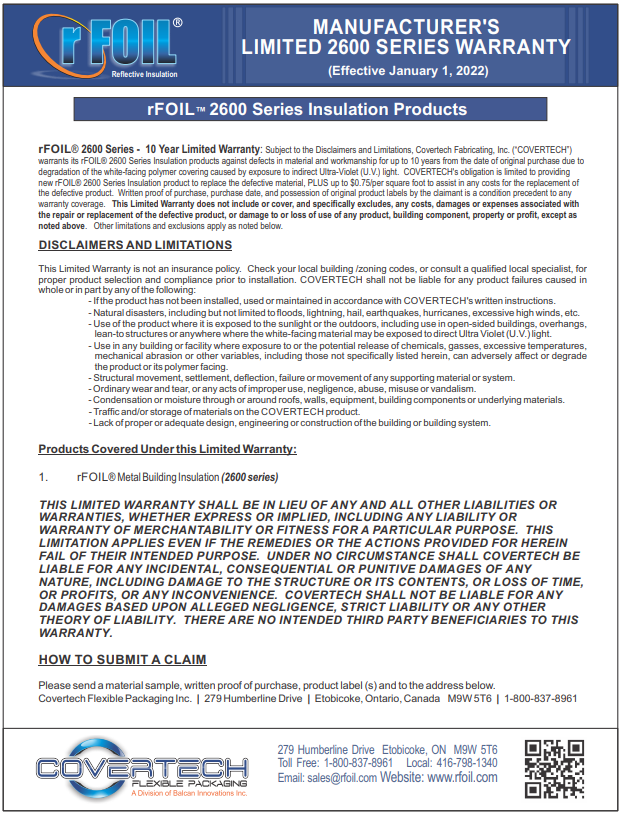

Full View2600 Series Warranty/Metal Building Insulation

The rFOIL 2600 Series Insulation products offers a 10 year manufacturer’s limited warranty which also includes a 10-year UV degradation warranty on material flaking and labor cost.

Click here for a downloadable pdf version of this warranty.

Full View Full Room Burn Test

These products have been tested to meet or exceed NFPA 286 standards:

| View | 1620 ultra CBF insulation |

| View | 1800 Ultra NT Radiant Barrier for SCIF’s |

| View | 2200 Reflective Insulation |

| View | 2290 STANDARD REFLECTIVE DUCT INSULATION |

| View | 2500 and 2600 Metal & Post Frame Building Insulation |

| View | 4320 Standard Concrete Underpad |

| View | 4800 NT RADIANT BARRIER |

| View | Big 6 2260 Reflective Duct Insulation |

| View | Big 8 2280 Reflective Duct Insulation |

Full ViewEasier Installations

Rely on rFOIL

Easier Installations start with a product you can rely on. Because we manufacture our own product on site in our Toronto facility, you can rely on a consistent quality product. Every time. We believe our quality testing far surpasses anyone else in the industry.

Commercial Grade

Our products are commercial grade. We target high end commercial customers as well as the most discerning residential customers. You won’t find our product lines in a box store. You will find our product at local distributors worldwide with the benefit of more personal care. Call us so we may put you in touch with an authorized distributor near you.

Made to Order

Don’t spend the time and effort returning a box-store based product when you can get the right product the first time with rFOIL every time for an easier installation. We do not store our products on warehouse shelves for months or years. Because of our unsurpassed manufacturing capacity, our product is delivered with the latest formulations and innovations in the best condition possible. Depending on the job, we also provide expedited customization of sizes and color. Contact us for details.

Installation Options

Many of our products are offered with installation options our competitors do not match. We make those options available because we know from experience that when the right options are chosen, it makes the installation process go quicker and better. We also manufacture our own accessories to match the product lines we sell.

The Right Product for the Right Job

Depending upon your job, our product lines may either supplement or replace the need for conventional batting insulation.

Click to Find RIGHT rFOIL Product for the JOB!

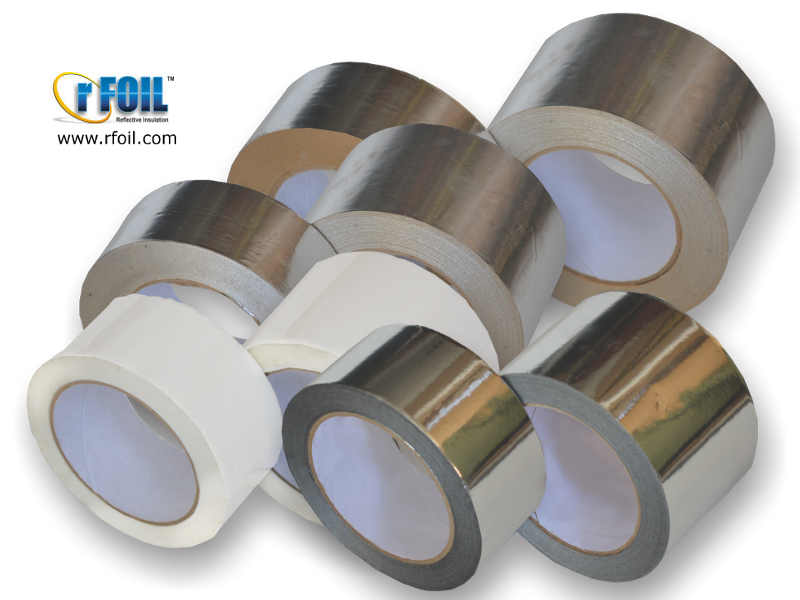

Full ViewThe RIGHT Adhesive Tape

Match the Tape to the Work

Four different types, two different widths, and two different lengths available.

Adhesive Tapes

| Name | Description | Size | Associated Products |

|---|---|---|---|

| rFOIL 11702 | Aluminum Conductive Foil Tape | 2″ wide | 1800 Series, SCIF Applications |

| rFOIL 15113 | Premium Metalized Tape for Duct Installation (HVAC) | 3″ wide | 2260, 2280, 2290 |

| rFOIL 15513 | Aluminum Foil Tape w/Liner for SCIFs | 3″ wide | 1800 Series |

| rFOIL 15512 | Aluminum Foil Tape w/Liner for SCIFs | 2″ wide | 1800 Series |

| rFOIL 15853 | White Poly Tape | 3″ wide | 1620,2500,2600, 4320, 4700 |

| rFOIL 15852 | White Poly Tape | 2″ wide | 1620,2500,2600, 4320, 4700 |

| rFOIL 15073 | Metalized Surface Building Insulation Seam Tape | 3″ wide | 2200,2500,2600, 4800 |

| rFOIL 15072 | Metalized Surface Building Insulation Seam Tape | 2″ wide | 2200,2500,2600, 4800 |

Choose the RIGHT rFOIL Accessory for the JOB!

Full ViewTested Quality

Radiant Barriers

- Surface Emittance – ASTM C1371

- Water Vapor Transmission – ASTM E96

- Surface Burning – Flame Spread- ASTM E84-09

- Smoke Density- ASTM E84-09

- Corrosivity -ASTM D3310

- Tear Resistance – ASTM D2261

- Adhesive Performance

- Bleeding – ASTM C1313

- Pliability – ASTM C1313

- Mold and Mildew – ASTM C1338

- Tensile Strength – ASTM D2261

Reflective Insulation

- Emittance – ASTM C1371

- Thermal Performance – ASTM C1363

- Surface Burning – Flame Spread – ASTM E84-09

- Smoke Density- ASTM E84-09

- Water Vapor Transmission – ASTM E96

- Temperature/Humidity Resistance – ASTM C1258

- Bleeding and Delamination – ASTM C1224

- Pliability – ASTM C1224

- Fungi Resistance – ASTM C1338

- Tearing Strength – ASTM D2261

- Corrosivity – ASTM D3310

Testing Required for Reflective Duct Insulation

- Surface Burning- Flame Spread – ASTM E84-09

- Smoke Development – ASTM E84-09

- Temperature Exposure- ASTM C411

- Test Method for steady-state Heat Transfer Properties of Pipe insulation – ASTM C335

- Water Vapor Transmission – ASTM E96

- Emittance – ASTM C1371

- Temperature/Humidity Resistance – ASTM C1258

- Bleeding and Delamination – ASTM C1224

- Pliability – ASTM C1224

- Fungi Resistance – ASTM C1338

** All testing done by NVLAP Approved Labs or Leading Universities

** For individual test reports please contact Covertech Flexible Packaging customer service.

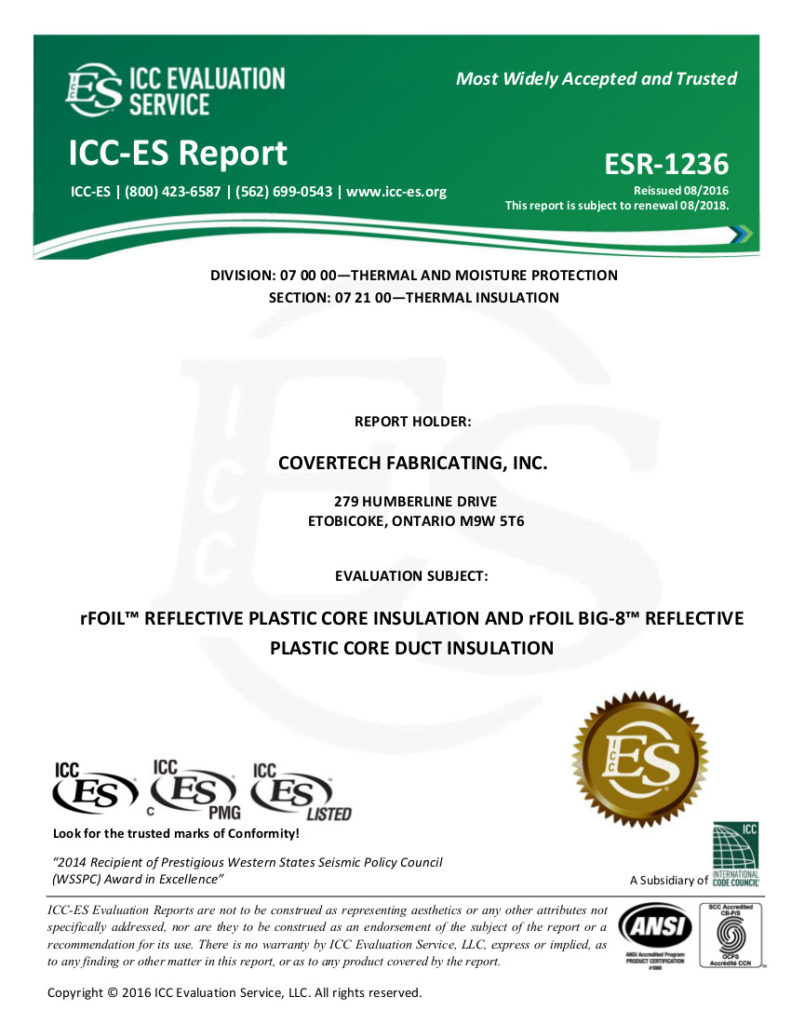

Certifications

-

- ICC – ES Evaluation Report – ESR -1236

-

- CSTB- Avis Technique 20/04-55*01 Mod

-

- State of California- Thermal Insulation Manufacture – license

- Rima International Verification Program For North America

Full ViewPatented Products

We Continue to Innovate, Grow, and Create Patented Products

Recognized for thermal performance, versatility, and environmental friendliness, our products are carefully manufactured onsite at our 107,000 ft2 facility.

| View | COVERTECH / rFOIL INSULATION Patent Portfolio |

| View | Manufacturer’s Certification Statement for the Taxpayer Relief Act |